Covering a site of nearly seventy three acres, Grangegorman is one of Ireland’s largest ongoing developments. A mixed use campus consisting of education, health, sports and residential it promises to be the new landmark in Dublin of third level education and living for Dublin Institute of Technology (DIT).

In one corner of the site, one structure nearing completion is the new DIT Research Hub building. Although it is not one of the largest on the campus it is certainly one of the most challenging from a services point of view. The five storey building houses laboratories, offices and lecture rooms. While conventional in certain areas with radiators and trench heaters providing heating to the spaces it is complex in other zones with vacuum, compressed air and natural gas to lab benches.

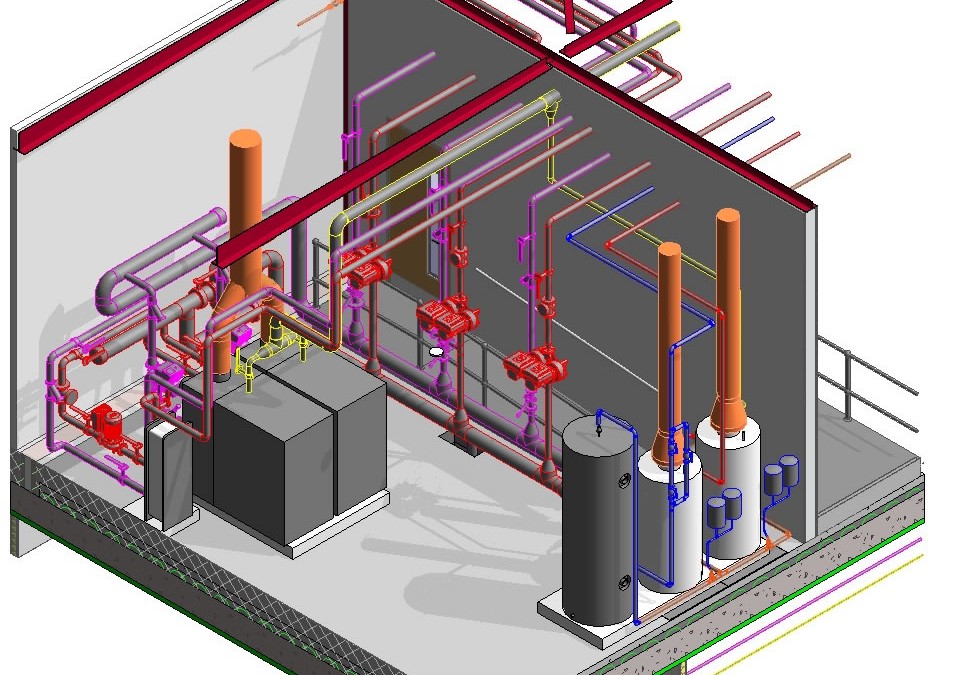

The low pressure hot water (LPHW) system is designed at condensing temperatures with two modern eco condensing boilers to allow for redundancy and services options. The design also incorporates natural ventilation, a heat recovery wheel and heat recovery coils on lab extract. The system design is also futureproofed with the provision of district heating mains connection via a plate heat exchanger. As part of the campus overall scheme, a central energy centre is planned with a network of distribution pipework to be linked throughout the site. Work has already commenced on parts of the scheme.

On the chilled side, a roof top chiller is positioned behind a louvered services courtyard which provides cooling to designated areas via fan coil units and air handling units with local control. While, the green element of buildings services includes a rain water harvesting part whereby rain water is collected from the roof, filtered and used in toilets. Hot water is preheated by a bank of solar tubes on the south facing penthouse rooftop and topped up when necessary by direct gas fired water heaters. The installed BMS system is also linked back to DIT for remote monitoring.

Unique to the building is the ventilation system. As there are several fume cupboards located throughout the laboratories, it is critical that their operation is correct. A bespoke duct mounted room ventilation control valve on both both supply and extract regulates the set room pressure. It compensates for changes in air pressure (fume cupboard operation) by increasing airflow when pressure drops within its specified range. This therefore maintains a constant air pressure in the space at all times.

While the services maybe complicated in areas the building was fully modelled on Autodesk Revit with T Bourke acting as lead services coordinator. The design drawings were merged and modelled at an early stage in a bid to speed up install, avoid clashes and stop program delays onsite. T Bourke’s managing director, Niall Bourke commented; ‘There were certain pinch points getting services into the lab areas but the coordinated BIM models really helped. I do believe it avoided clashes and speeded up install onsite.’ The services are exposed in large areas of the building so any errors could be visible later.

The building is nearing completion, with filling, flushing, chemical cleaning, commissioning and testing commencing shortly. Its finish will see one more element of the DIT faculty move out of their city centre campuses which in the long term will see the creation of a new hybrid campus in Dublin’s north side.

- Main Contractor: BAM

- Architects: BDP, RKD (Client)

- Services Consultant: Ethos Engineering, Arup (Client).

- Mechanical Contractor: T BOURKE

- Electrical Contractor: Precision